Whether it’s purchasing furniture, decor, or interior renovations, we encounter different types of wood panels, such as solid wood, plywood, MDF, or laminate flooring, among others. With so many options, are they all genuinely made of solid wood? Why do we have so many different types? Here, I will list common wood panels, highlight their pros and cons, and provide clarity to aid in choosing the right materials.

First, it’s important to understand that “wood is a breathing material.” Wood expands and contracts with changes in humidity and temperature. When wood absorbs moisture, it swells, which can result in uneven surfaces or a wobbly table. Temperature fluctuations cause the wood to expand or contract, leading to slight dimensional changes. If these variations are not severe, the wood will return to its original state when the climate normalizes. However, if the changes are significant, such as prolonged exposure to water, the wood may not be able to revert to its original form.

To mitigate the effects of humidity and temperature on wood panels and to achieve cost-effectiveness and durability, people have developed various types of panels suitable for different environments. Some panels emphasize strength, durability, and affordability, while others prioritize weather resistance or the natural beauty of wood grain.

Now, let’s categorize the panels into three major types based on the amount of natural solid wood content. Although there are countless types of wood panels, dividing them into these three categories can provide a good starting point for selecting the appropriate materials.

<第一大類 天然實木板> Solid Wood Panels: These panels are made entirely from natural solid wood without any additional veneer.

When it comes to solid wood, there is a special pricing method. Larger and thicker pieces of wood command higher prices compared to smaller pieces of the same volume. The surface appearance, presence of knots, aesthetic wood grain, uniform distribution, and grading also play a role.

Solid wood panels offer the most prominent natural beauty. In addition to visual wood grain, they provide a tactile experience with the natural fibers following the wood grain and a pleasant, non-toxic aroma. However, untreated solid wood panels are highly susceptible to climate influences. Therefore, most solid wood products have a protective finish to isolate them from external air and prevent moisture absorption.

Solid wood panels exhibit the natural beauty of wood grain, which can deform along the wood fibers due to climate changes. Thus, during the processing of solid wood, the freshly cut wood pieces undergo drying. Even after one or two years of drying, finished products may exhibit slight warping. Understanding the potential variations and implementing preventive measures is crucial for solid wood products.

Since the width of solid wood panels from the sawn log is generally insufficient for furniture production, they often undergo a process called finger jointing, where narrow boards are joined to form wider panels. There are two common finger jointing methods: straight jointing and finger jointing. Straight jointing closely mimics the natural wood grain by minimizing the number of glued joints, allowing the natural wood grain to be showcased. Finger jointing, on the other hand, is a more cost-effective approach that uses smaller wooden blocks to form the panel. This method utilizes smaller, more easily obtained wood pieces.

<第二大類 夾板/合板> highly crafted wood panels

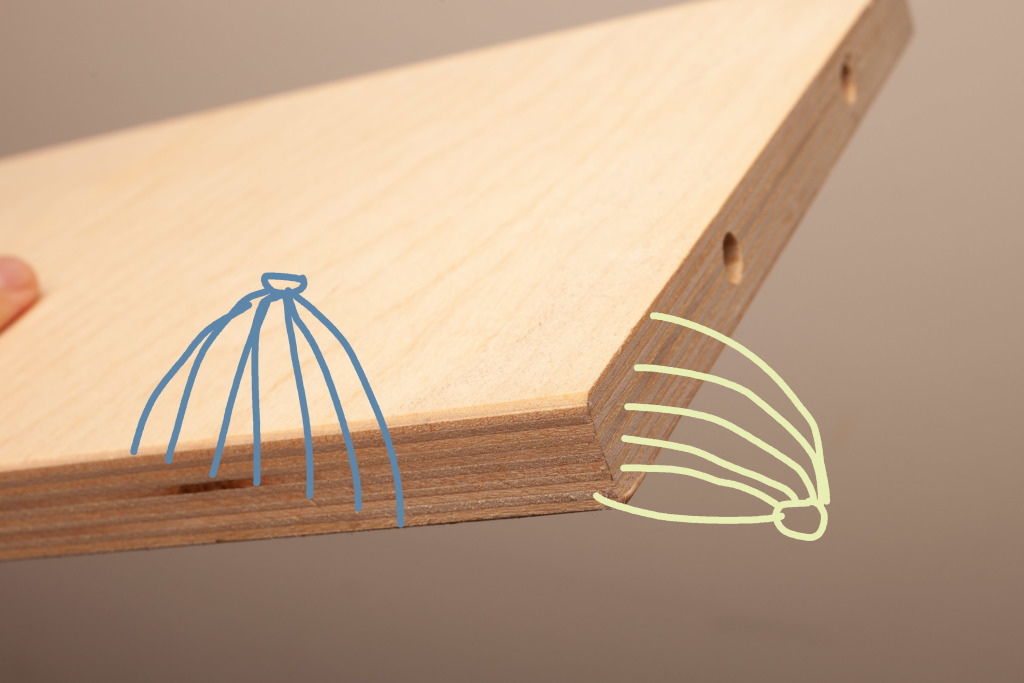

Plywood: Plywood is created by highly engineered bonding methods that reduce the cost of large-area panels while maintaining aesthetics and durability. It overcomes issues related to warping. Plywood resembles layers of a mille-feuille pastry, with each layer contributing to the required thickness.

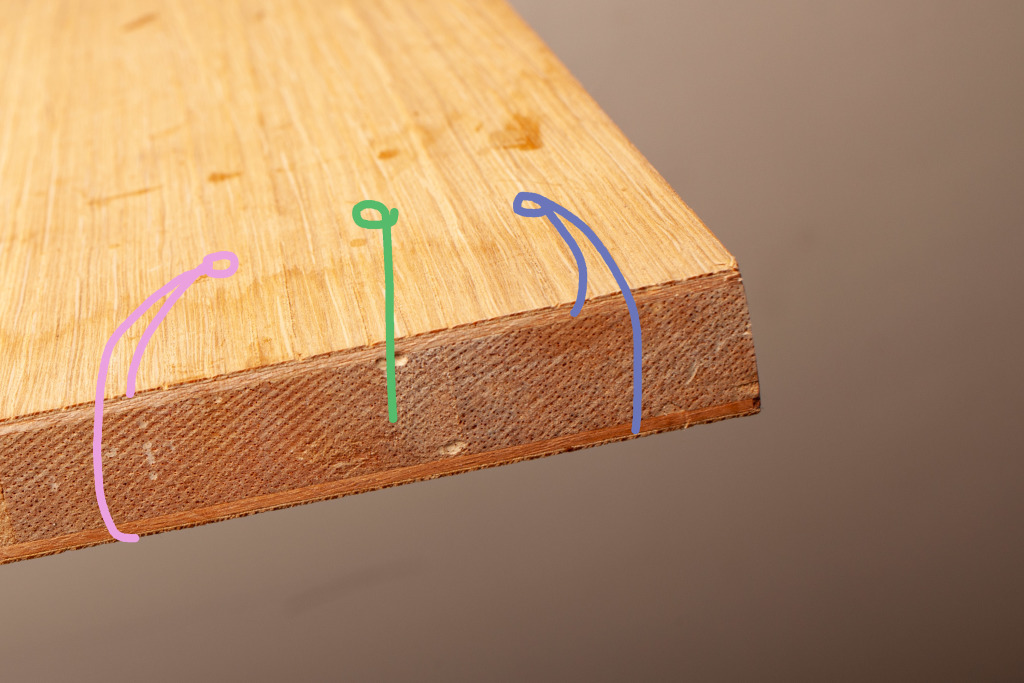

Veneer Panels: Veneer panels consist of a core made of small wood pieces joined together, with a thin layer of natural wood veneer applied to the surface. This mimics the appearance of solid wood panels. The outer veneer is obtained from real solid wood, sometimes requiring thicker veneer pieces to enhance the three-dimensional effect of the wood grain.

Some additional knowledge: What is "crystal piano panal," an option for system cabinets, and why is it more expensive?

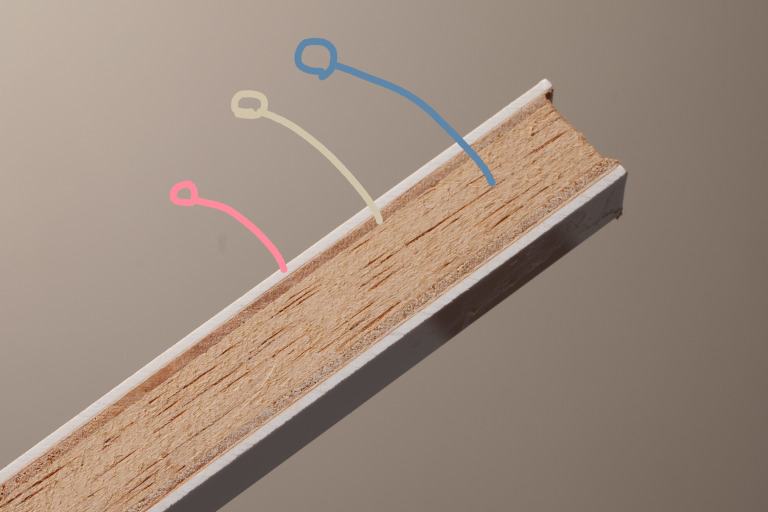

When selecting panel materials for system kitchen cabinets, one option is “crystal piano panal” which is typically priced higher. crystal piano panal refers to the surface treatment of a wood-core panel, which is then covered with a layer of plastic or resin. This complete encapsulation provides excellent waterproofing properties. Additionally, as it retains the wood-core structure, it is lightweight and less prone to warping. The plastic surface allows for a variety of color and pattern choices, making it an excellent panel material option.

The third category includes materials like MDF (Medium-Density Fiberboard) and particleboard. These materials contain wood particles that are mixed with a large amount of adhesive and then pressed or molded using heat. The biggest advantage of these panel materials is their low cost. The cost-effectiveness stems from using wood particles of various sizes, including scraps and offcuts. However, they may have lower strength compared to other materials.

<第三大類 人造板材> There are also panel materials with a significant non-wood component.

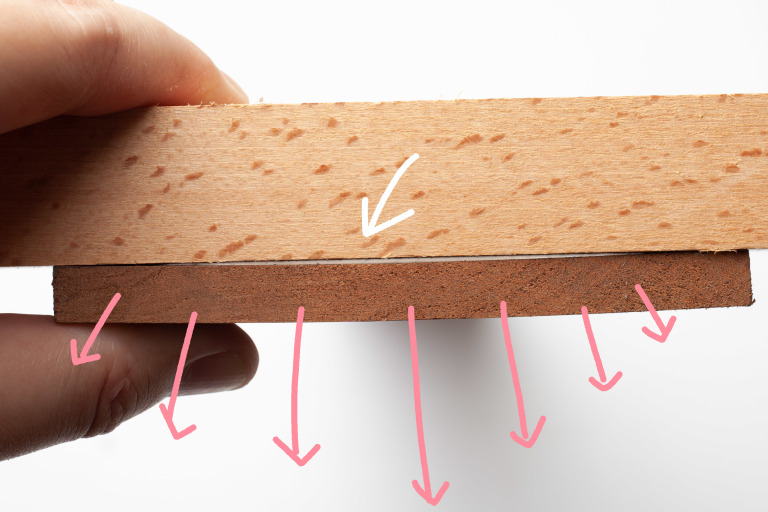

Laminate Flooring: Laminate flooring is a commonly seen application. To withstand daily foot traffic and heavy loads, laminate flooring must fulfill several functions. It requires a hard and wear-resistant surface to prevent imprints from foot traffic. It needs a stable bonding structure to ensure flatness. It should offer a certain level of flexibility to provide a comfortable walking experience. Additionally, it needs soundproofing capabilities. Lastly, it must resist deformation caused by moisture absorption or thermal expansion and contraction. Laminate flooring is, in fact, a multi-layered structure that includes treated composite panels and buffer layers to increase thickness and provide elasticity.

Honeycomb Tabletops: Have you ever wondered why some small tables, such as those from IKEA, can have a certain thickness while remaining lightweight and cost-effective? These tables often utilize a honeycomb structure, which combines a thin surface layer with a honeycomb core. The honeycomb structure provides strength and stability while reducing weight and cost.

Decorative Panels: Decorative panels like melamine boards are widely used in interior design. They consist of layers of specially sealed printed paper and kraft paper. Since they can be easily applied to other panel materials, they are resistant to dirt, high temperatures, and scratches. Moreover, they offer a myriad of styles to choose from. Decorative panels are commonly used in interior decoration projects.

Conclusion

After examining various wood panels, it is essential to have a concept of material selection and discussions about material choices in interior design. Every material has its advantages and disadvantages, and the key lies in using them appropriately. There are no inherently “bad” materials; the problem arises when they are used in the wrong context.

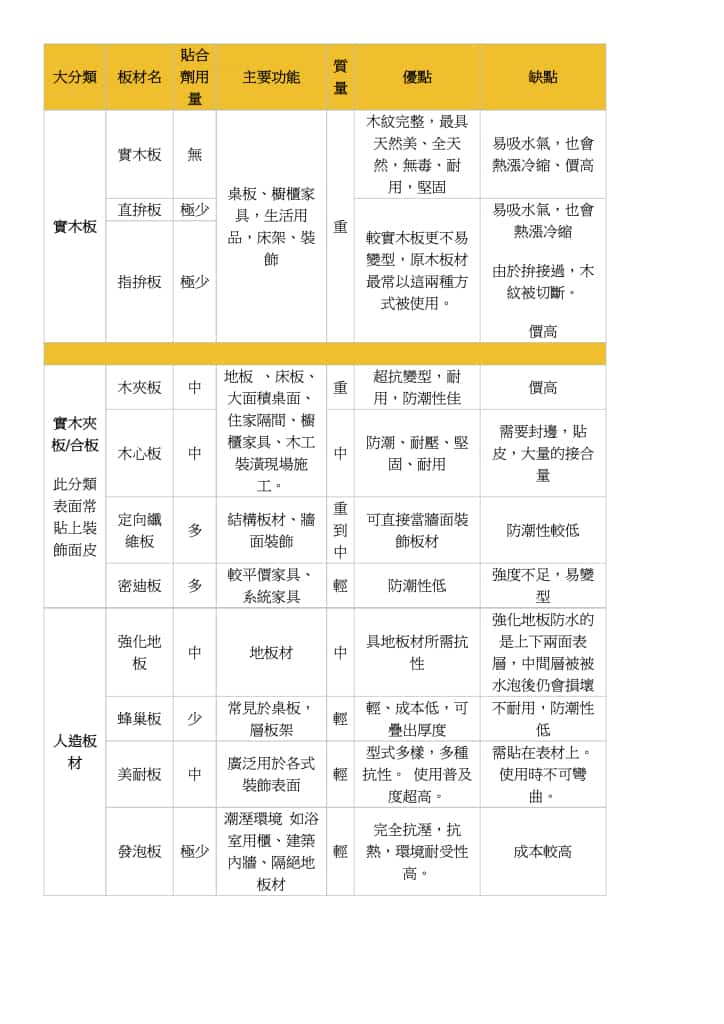

The comparison table below provides a practical reference when discussing material choices for interior design projects.

What materials does 9house use for furniture?

Our Egret Clothes Rack and Pet Bowl Stand series are made using different types of solid wood materials.

For the Egret Clothes Rack, we emphasize the expression of natural wood grain, so we chose white wax wood as the main material. White wax wood exhibits distinct wood grain with visible variations in the surface texture, providing asense of depth when touched. As for the horizontal bars, we opted for a slightly darker shade of beech wood. The combination of these two wood materials, both belonging to the light color range, showcases the natural layering of colors and variations in wood grain. Coupled with the three-dimensional wood grain texture and the subtle scent emitted from the non-toxic water-based finish, these details enhance the minimalist design.

Water resistance is a crucial consideration when creating pet bowl stands. For our Pet Bowl Stand, we exclusively use Japanese oak. Japanese oak offers fine wood grain, a smooth surface, and minimal pore structure, making it less prone to retaining water within the grain. During the manufacturing process, we also use thicker dimensions to minimize the possibility of warping due to moisture absorption.

-

Little Egret Cloth Stand ( All Height Setup)

NT$2,750 – NT$5,800 -

Round Bowl Stand – All Type

NT$1,950 – NT$6,250 -

Butterfly Pet Bowl Stand – All Type

NT$1,500 – NT$5,550